GORE® LYOGUARD® Freeze-Drying Trays

Single-use, enclosed freeze-drying trays that keep product in the tray during the lyophilization process.

Contatti

Americas

+1 800 294 4673

+1 410 506 1715

Europe

+49 89 4612 3456

+800 4612 3456

US

+1 800 294 4673

+1 410 506 1715

Overview

PROTECT YOUR OPERATORS AND ELIMINATE TRAY CLEANING

Keeping liquid or lyophilized API in stainless steel trays is a challenging and time-consuming problem during processing. GORE LYOGUARD Freeze-Drying Trays were designed in consultation with industry experts to contain product during the freeze-drying process. For nearly 20 years, manufacturers have trusted GORE LYOGUARD Trays to help minimize the risk of exposure to APIs and Highly-Potent APIs, and to enable operators to spend less time worrying about product ejection and cleaning.

These disposable trays are ideal bulk lyophilization containers, because the GORE Membrane — an integrated 100% ePTFE tray cover — can enable improved process efficiencies and yields, and reduced risk of operator exposure.

ADDRESSING UNMET NEEDS IN BULK TRAY LYOPHILIZATION

Understand the benefits of single-use disposable LYOGUARD Freeze-drying trays compared to stainless steel trays for lyophilization

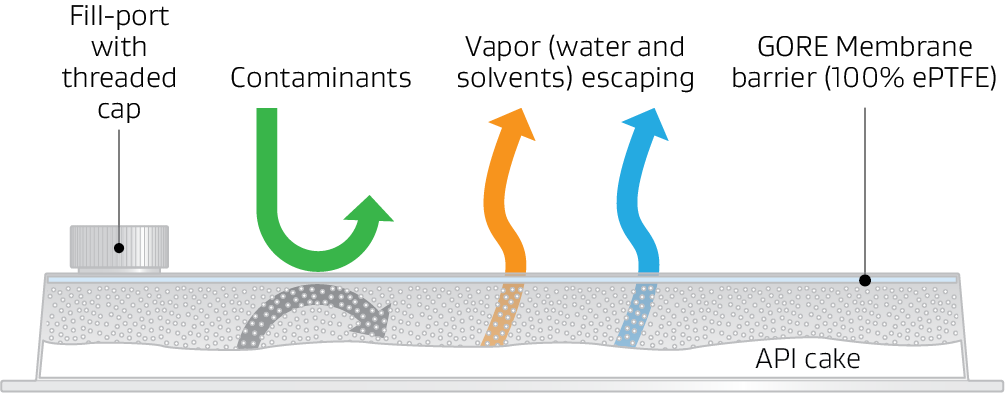

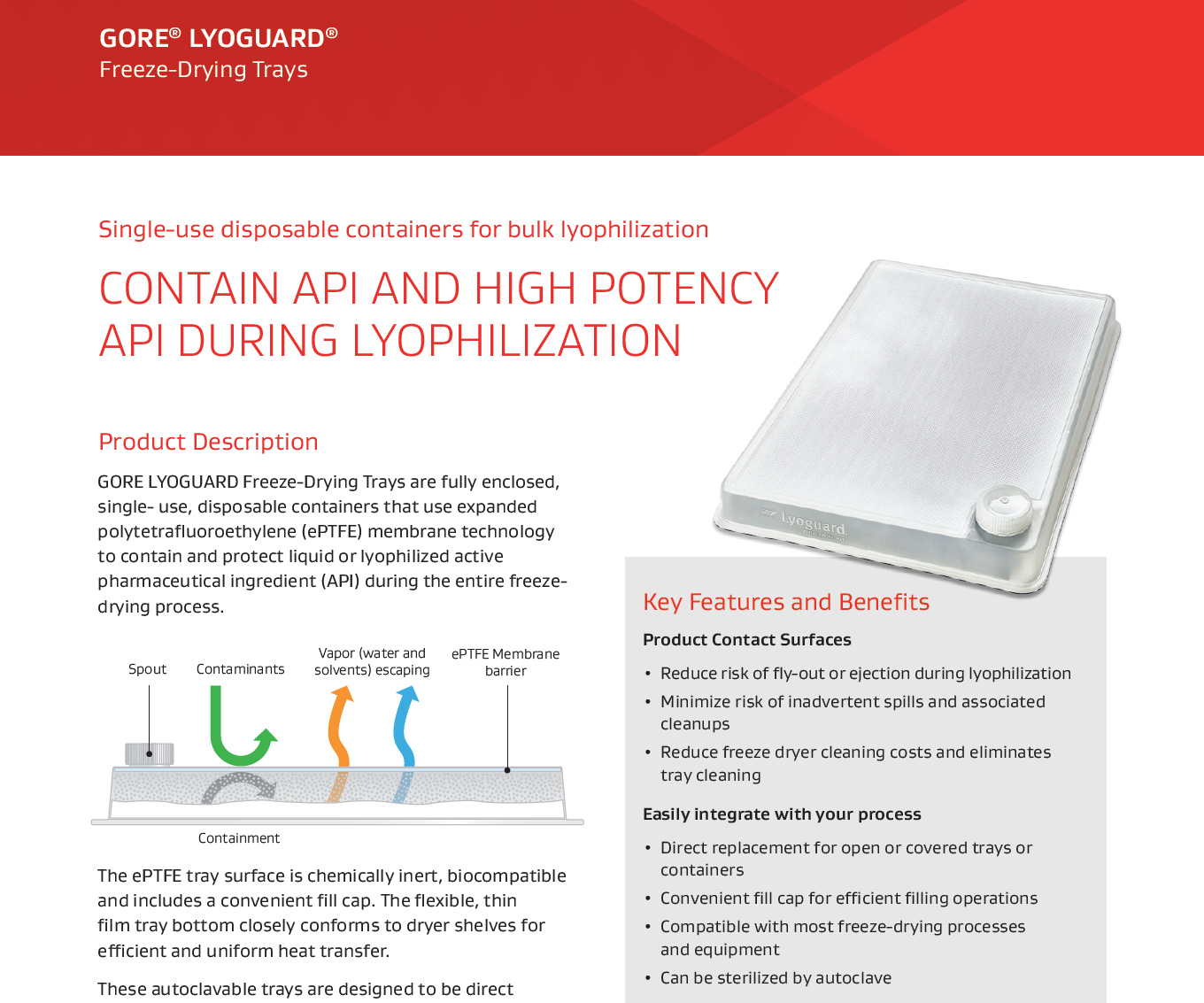

Unique to this lyophilization tray is its GORE Membrane — an integrated 100% ePTFE tray cover that provides:

- a built-in protective barrier that keeps contaminants out

- a permanently-attached cover to safely contain product, unlike steel trays

- a high vapor transmission rate, so water and solvent vapors are readily released

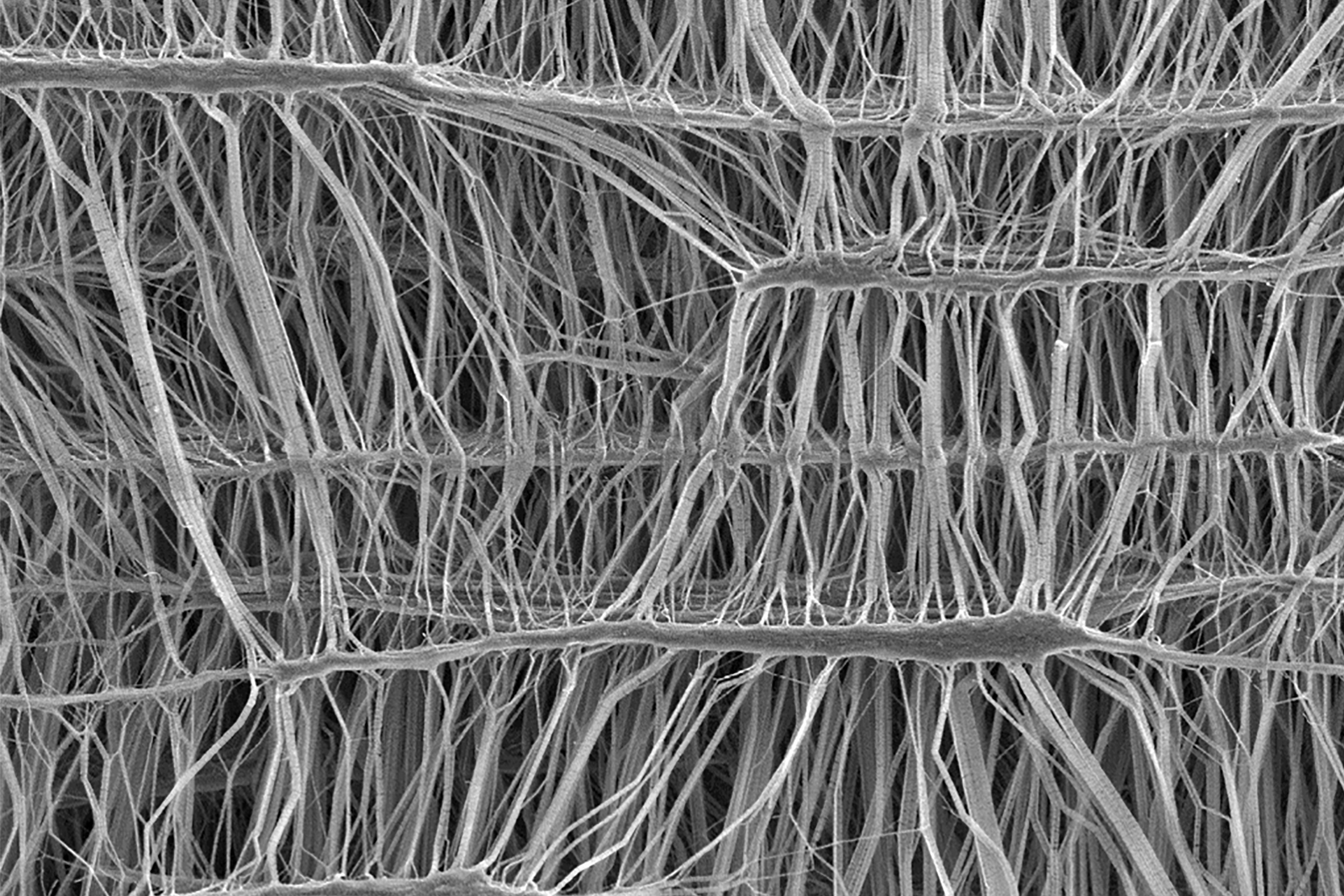

Gore's unique microporous ePTFE membrane enables high-efficiency lyophilization yet provides a barrier to keep product in the tray.

LYOPHILIZATION TRAY APPLICATIONS

GORE LYOGUARD Freeze-Drying Trays can simplify processing by eliminating many cleaning operations, and can enable greater safety in handling a wide variety of fluid and lyophilized drug products, including:

- polypeptides

- oligonucleotides

- vaccine adjuvants including lipid nanoparticles

- microbiome therapeutics

The integrated GORE Membrane enables exceptional mass transfer while the thin, conforming tray bottom facilitates efficient thermal transfer

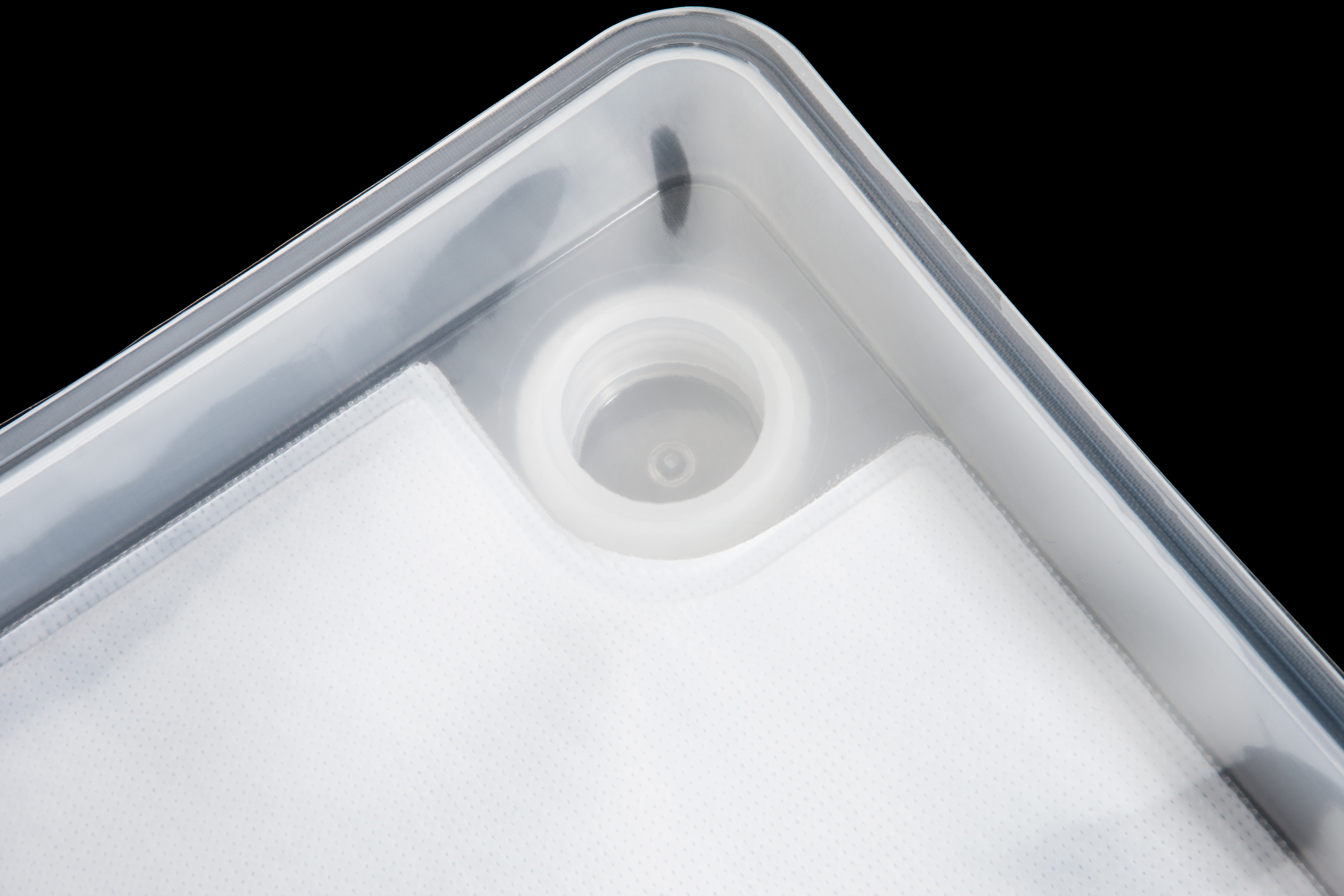

Filling and freeze-drying within GORE LYOGUARD Trays is easy and efficient, as the tray design can reduce the chance of contamination and the risk of operator exposure — or loss of valuable product — due to fly-out or ejection.

For virtually any lyophilized drug formulation or lyophilized drug development process, GORE LYOGUARD Freeze-Drying Trays totally eliminate tray cleaning, and can reduce the chance of accidental spills and related cleanings of the lyophilization chamber.

Lyophilization tray for bacterial applications

An area of intense clinical focus is preservation of bacteria by lyophilization, whether for traditional therapeutics or emerging microbiome applications relating to gut microbiota, gut flora or live biotherapeutic product. GORE LYOGUARD Freeze-Drying Trays are designed to support a wide range of formulations for freeze-drying of bacteria and lyophilization of nanoparticles because they can enable greater operator safety and process efficiency, and reduce risk of product contamination — all of which are essential in lyophilization of bacterial culture.

GORE LYOGUARD Freeze-Drying Trays benefits:

| CONTAINMENT | |

|---|---|

| Integrated membrane top allows for high vapor transmission while also providing containment |

|

| THROUGHPUT | |

| Single-use, disposable (SUD) trays save time |

|

| COMPATIBILITY | |

| Easily integrated with your processes |

|

| CONFIDENCE | |

| Gore quality is assured |

|

How it Works

THE PERFORMANCE ADVANTAGES OF GORE

GORE LYOGUARD Freeze-Drying Trays are a direct replacement for open or covered stainless trays traditionally used for bulk lyophilization of API. Neither open trays nor trays with improvised wraps or covers can match the unique combination of performance benefits that GORE LYOGUARD Freeze-Drying Trays provide.

The tray top

The tray top includes an integrated GORE Membrane and a fill-port with threaded cap to make tray-filling easy and convenient. The GORE Membrane has a specialized microporous structure that is ideal for use in freeze-drying applications. It is engineered to optimize vapor transmission so water and solvents can escape readily, while at the same time it creates a barrier to reduce product fly-out or ejection during lyophilization. This minimizes the risk of inadvertent spills and associated cleanups.

The GORE Membrane

The surface of this 100% ePTFE membrane is engineered to be:

- chemically inert

- biocompatible

- non-particulating

- thermally stable

The Tray Base

The tray base of flexible, thin film closely conforms to dryer shelves, for efficient and uniform heat transfer.

GORE LYOGUARD Freeze-Drying Trays provide the optimal balance of barrier protection and breathable vapor transmission. This keeps product in the tray while allowing for efficient lyophilization.

Product Comparison

Performance Advantages

The GORE LYOGUARD Freeze-Drying Tray is a unique replacement for open stainless-steel trays and other containers traditionally used for the lyophilization process. Neither open trays nor trays with improvised wraps or covers can match the unique combination of performance benefits that GORE LYOGUARD Freeze-Drying Trays provide.

GORE LYOGUARD FREEZE-DRYING TRAYS vs. Alternatives

| GORE LYOGUARD Trays | Tray Covers or Improvised Wraps | |

|---|---|---|

| Handling | Integrated top — no need for separate covers | Require extra handling to install/remove |

| Cleaning | Covered trays are single-use; no cleaning | Require extra labor to clean after use |

| Spills/Fly-Outs | Effectively block contents from escaping | Vulnerable to leaks, spills, fly-outs |

| Contamination | Effectively reduces risk of product contamination | Vulnerable to external contaminants |

| GORE LYOGUARD Trays | Open Stainless-Steel Trays | |

|---|---|---|

| Filling Requirements | Integrated top membrane reduces splash risk; no special precautions needed Enable filling at higher speeds for greater productivity |

Low speed filling in Class-A environment, close to dryer loading area, required to minimize splashing |

| Tray Handling | Integrated top membrane contains and protects product, effectively reducing risk of splash/fly-out incidents for more flexibilty during filling, loading, unloading, or transport Trays can be stacked for transport and during post-lyophilization storage |

Requires multiple slow and careful manipulations to fill, load, download, and transport open trays without incident Open trays cannot be stacked |

| Impact on Thermal Transfer | Flexible, thin film base provides uniform tray-to-shelf contact, minimizing air gaps and improving thermal transfer | Metal trays may warp creating inconsistent tray-to-shelf contact, resulting in poor thermal transfer |

| Contamination | Efficient barrier protection effectively reduces risk of contamination | Highly vulnerable to contamination of product |

| Fly-Out | Reduced risk of fly-out means:

|

Highly vulnerable to fly-out, which can:

|

| Product Recovery | Fast, simple recovery process: use integrated fill-port or cut bottom film to recover product | Spatula use requires a slow, careful process |

| Remedial Cleanings | By protecting against spills and fly-outs, the need for additional remedial cleanings or validations is effectively reduced | After spills or fly-out, cleaning of freeze dryer requires additional validation, consuming worker time and resources |

Replace Stainless Steel Trays

An Innovation for Lyophilization

Open stainless-steel trays are the norm for lyophilization, but that doesn’t mean they’re ideal. Introduce yourself to the only single-use, self-contained tray on the market. GORE LYOGUARD Freeze-Drying Trays offer a number of benefits for the synthesis of peptides and oligonucleotides.

Contain Product — and Costs

In traditional freeze-drying processes using open trays, drug product can escape the tray into the lyophilization chamber. GORE LYOGUARD Freeze-Drying Trays help prevent product ejection for less mess and less product loss.

Easier Filling, Less Spilling

Filling open trays can leads to product spills, which creates messes, wastes product and exposes workers to potentially hazardous APIs. GORE LYOGUARD Freeze-Drying Trays feature an innovative top membrane and spout that makes tray filling easier and safer.

Get a Handle on Handling

Stainless-steel trays are challenging to handle because drug product can spill, exposing operators to active pharmaceutical ingredients. GORE LYOGUARD Freeze-Drying Trays enclose liquids completely, preventing spills and making tray handling more efficient.

Never Clean Another Tray

Single-use lyophilization trays don’t need to be cleaned, which saves pharmaceutical companies and drug manufacturers time and money. GORE LYOGUARD Freeze-Drying Trays are the only single-use, self-contained tray on the market.

Want to know more?

For additional product information and specifications

For general questions about our trays and their applications

For a sample please email us a completed form.

Resources

Data Sheet: GORE® LYOGUARD® Freeze-Drying Tray

Data Sheets, 188.58 KB

Validation Guide: GORE® LYOGUARD® Freeze-Drying Trays

Validation Guides

Handling Guide: GORE® LYOGUARD® Freeze-Drying Trays

Technical Information, 99.01 KB

Sterilization Guide: GORE® LYOGUARD® Freeze-Drying Trays

Technical Information, 466.58 KB

News recenti

NOT INTENDED FOR USE in medical device or food contact applications or with radiation sterilization.

Segui GORE® LYOGUARD® Freeze-Drying Trays